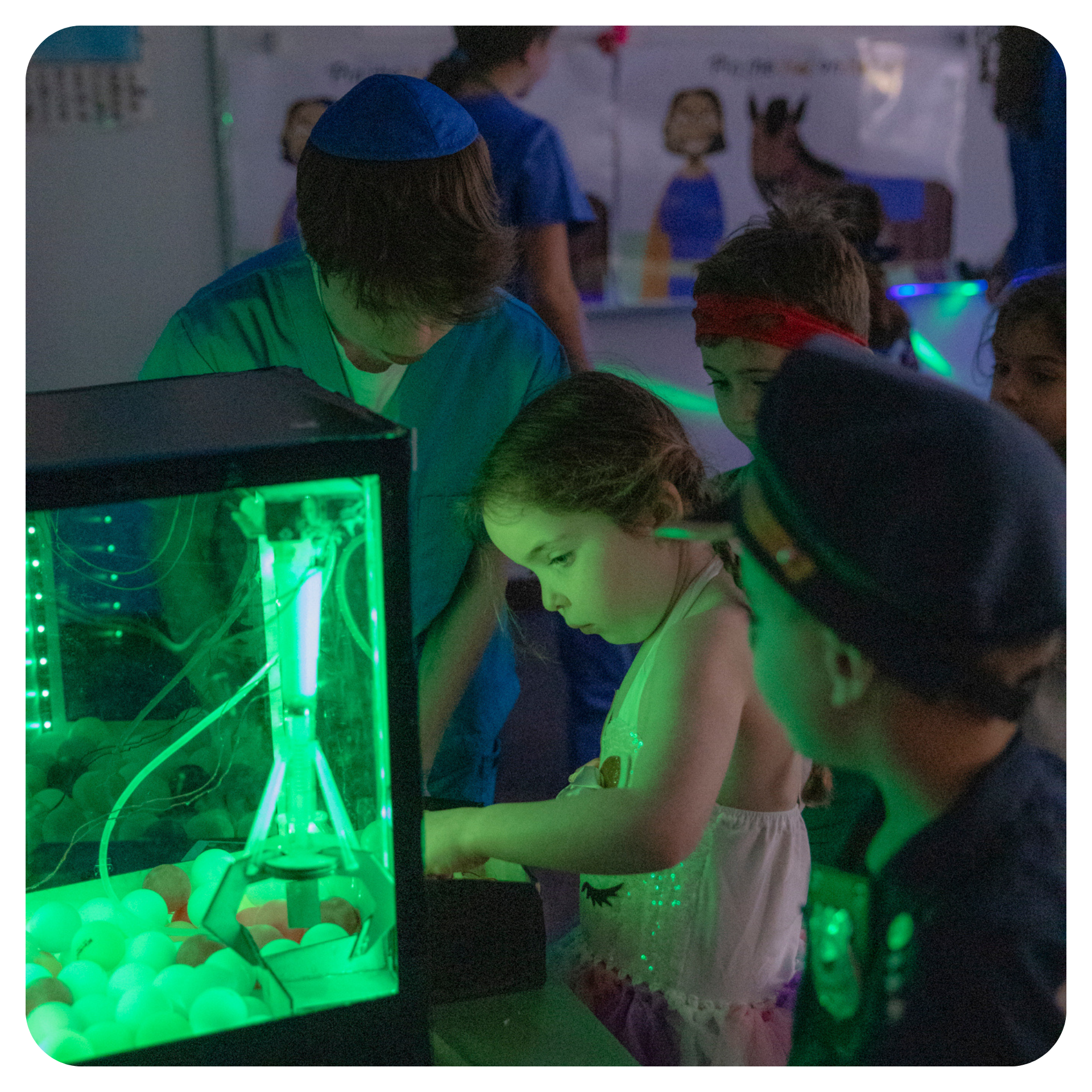

Claw-some Creativity: Schechter Students Build a Working Claw Machine

Behind the Build: Crafting a One-of-a-Kind Claw Machine

For Benny E, Mark G, Jared N, and Ari S (’25), building a claw machine wasn’t an assignment or a requirement—it was simply a challenge they wanted to take on. What started as a fun idea turned into a fully functional machine, built from scratch by four students who were eager to create something exciting.

From Idea to Blueprint

The inspiration behind the project was simple: “We just thought it would be fun and exciting to build a claw machine.” With that goal in mind, the team spent weeks planning and refining their designs, knowing that adjustments would be inevitable along the way. Even as they started building, they continued to modify their approach, problem-solving in real-time to make the best possible version of their vision.

Facing the Challenges Head-On

While the team had some prior experience working with equipment and wiring, this was their first large-scale project. Each step came with its own learning curve, especially when technical difficulties arose. “There were many instances where wires didn’t work right, or we accidentally built something the wrong size,” they explained. But their persistence paid off. Even when a wire snapped at the last minute, they worked quickly to repair it and ensure the machine was fully operational. Their mindset? “The trick to overcoming challenges was to not give up and continue to try different ways.”

Strengths in Teamwork

Each student played a critical role in bringing the machine to life:

🔧 Mark G took charge of the technical and mechanical components, making sure the wiring functioned properly and keeping the team focused.

🛠️ Jared N built the main frame, along with the intricate smaller parts.

🎨 Benny E handled the exterior, ensuring the machine had a polished and professional look.

📐 Ari S served as the architect, developing the initial designs that guided the entire build.

A Moment of Success

For all the obstacles they faced, the most rewarding moment came when the claw’s axis moved in all directions for the first time—a sign that their design, problem-solving, and teamwork had paid off. The experience not only allowed them to develop hands-on technical skills but also reinforced the value of perseverance, collaboration, and creative thinking.

Their claw machine stands as a testament to what can be accomplished with an idea, a plan, and the determination to see it through.